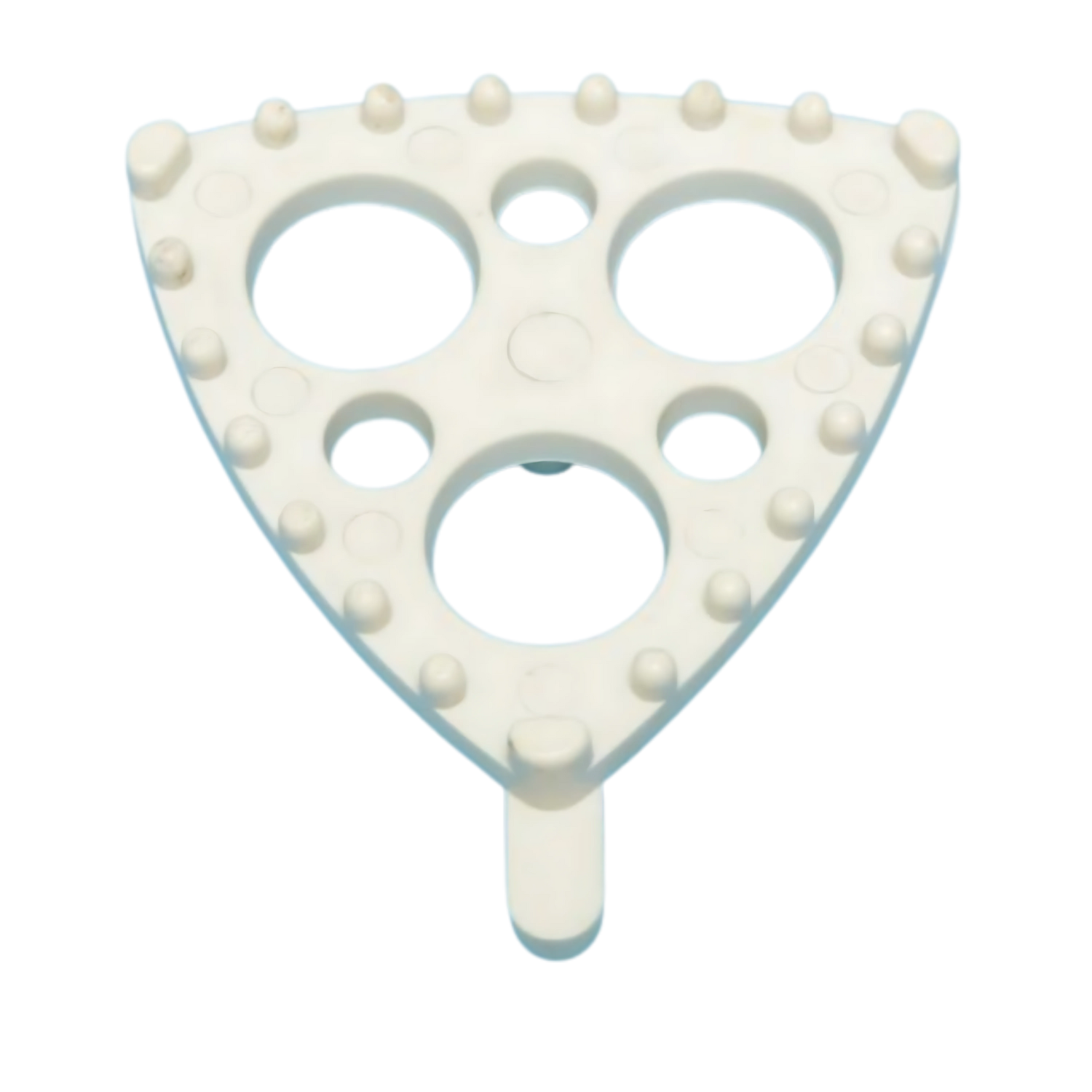

Large triangular for bigger sieves; molded studs for impact cleaning.

The Big Triangular Cleaner with Studs is engineered for fast, reliable maintenance of sieves and other fine‑mesh equipment used across food processing, milling, pharmaceuticals, laboratories, and quality‑control environments. Its large triangular profile maximizes surface contact, while a pattern of raised studs provides gentle but effective mechanical agitation to dislodge trapped particles without damaging sensitive mesh.

Strategically placed circular cutouts reduce weight for extended use, improve handling, and allow air flow that helps prevent suction on tight meshes. A smooth, tapered tail tab gives operators a confident grip and precise control, even when wearing gloves. The one‑piece molded body resists wear, deformation, and edge fraying—key traits for tools that see repeated daily use in production settings.

Unlike improvised cleaning methods that can puncture or stretch screens, this cleaner distributes pressure evenly across the surface. The rounded studs minimize abrasion while still lifting stubborn residue from corners and edges. The result is quicker screen turnaround, consistent product quality, and less downtime between runs.

Whether you’re clearing flour residue in a plansifter, removing fines from a classifier screen, or maintaining lab sieves between batch tests, the Big Triangular Cleaner with Studs delivers the right blend of rigidity and finesse. Lightweight, easy to sanitize, and built for long service life, it’s a cost‑effective addition to any preventive‑maintenance toolkit.

Use it on flat or slightly contoured screens, in dry or lightly damp conditions, and pair it with your standard cleaning and inspection SOPs to keep throughput high and mesh integrity intact.